Quality Result Sdn. Bhd. was incorporated on 19th March 1992 as private limited company. The company is principally engaged in manufacturing and sales of injection moulded plastic products and other plastic related business activities.

The founder of the company, Mr. Goh Tiong Hwee has been adopted the name QUALITY RESULT, which means the high quality products. He has been possesses more than 30 years in technical of the plastic industries. The founder gained considerable experience in business management.

Quality Result has mainly involved in production of plastic moulded industrial parts, and some parts moulded consists of calculator, hand labeler, shower set, water heater, audio, video, remote control, automotive parts and precision parts. These moulded plastic parts that we supply to our customers were being exported. As such, we estimated conservatively that 70% of our moulded plastic parts are for export markets such as Asia Pacific Region and Europe.

We have been working toward ISO 9001:2000 since year 2004. Besides that, we are using specialty raw material, e.g. PBT, PET, PMMA, PC, 30% & 10% G/F, Noryl, Nylon, POM, ABS UV, PP, PC/ABS, Santoprene.

The world deserves an ideal and satisfying product for a better life style.

We dedicate ourselves to provide an excellent solution for supporting every market leader with our injection moulding and secondary process through a competitive prices and delivery quality services in a shortest leadtime.

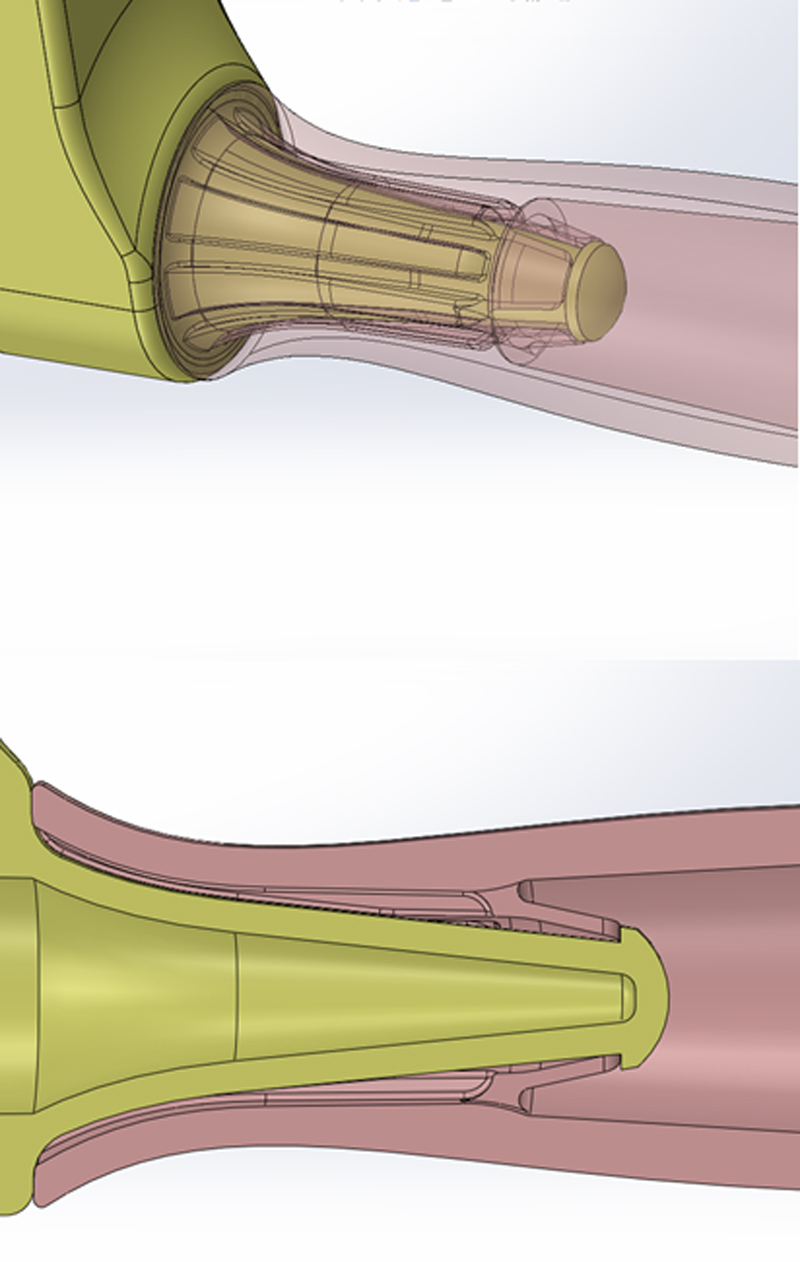

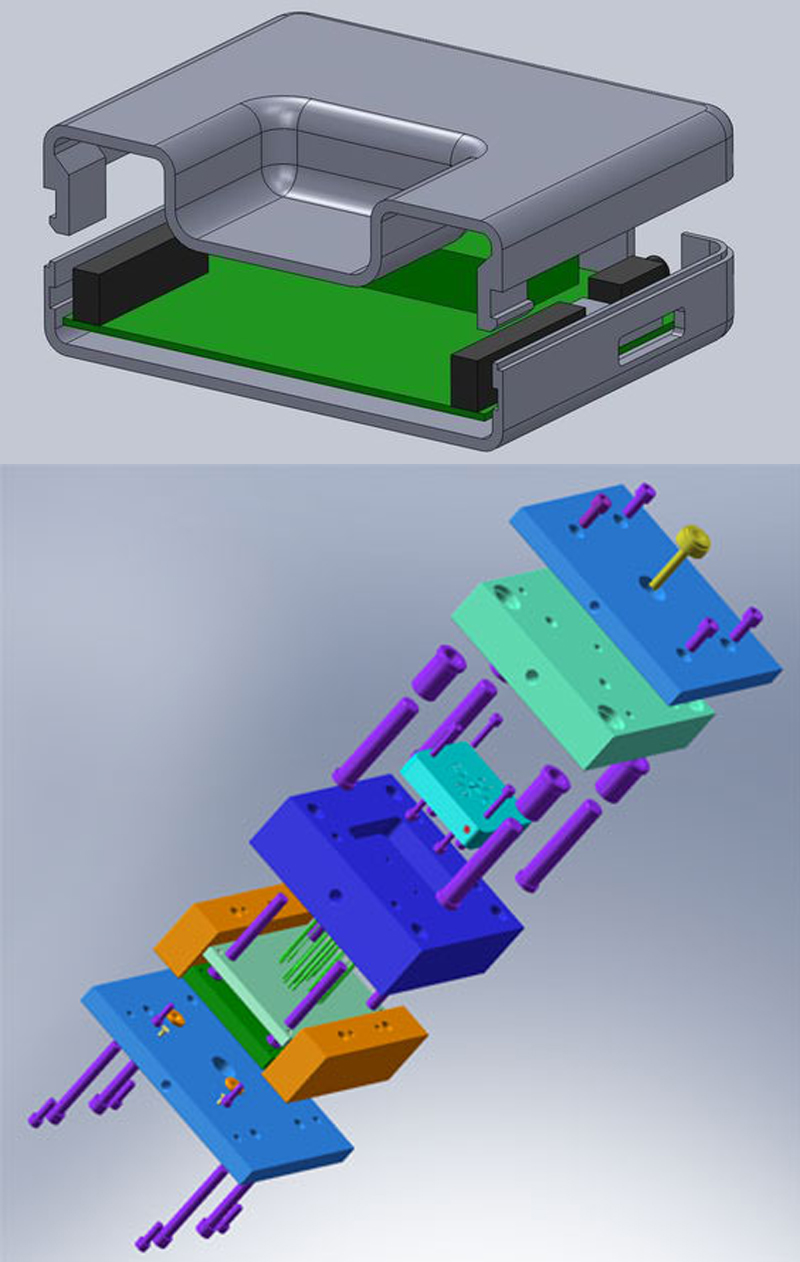

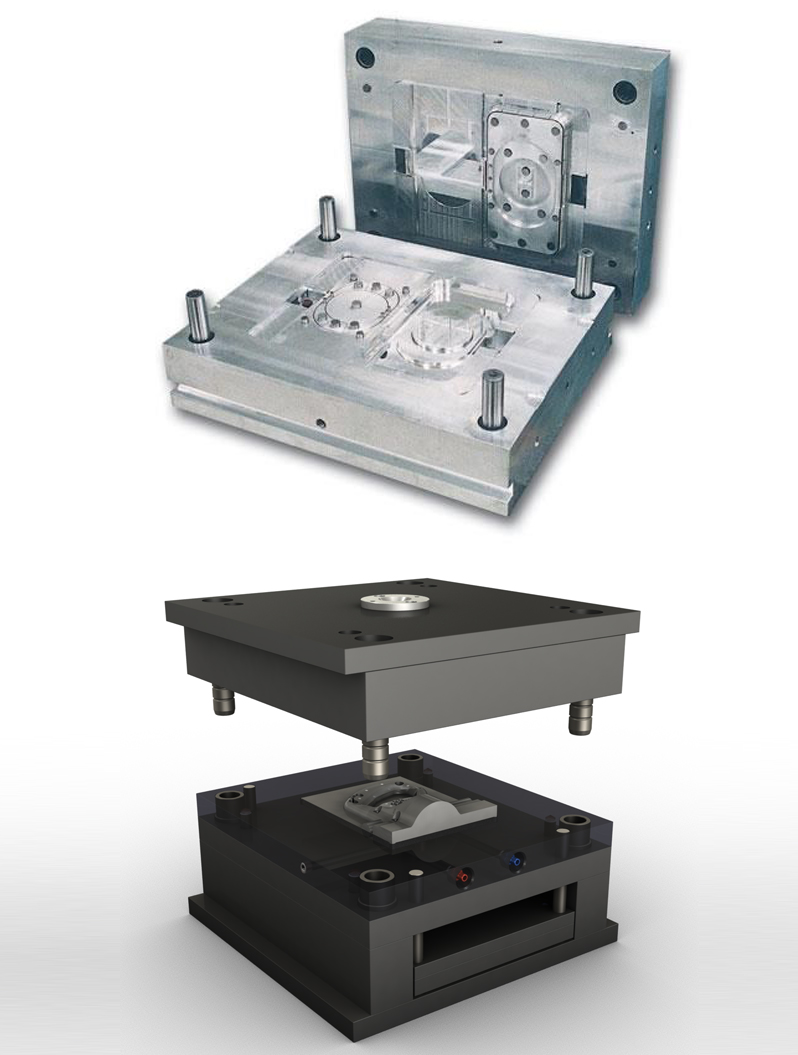

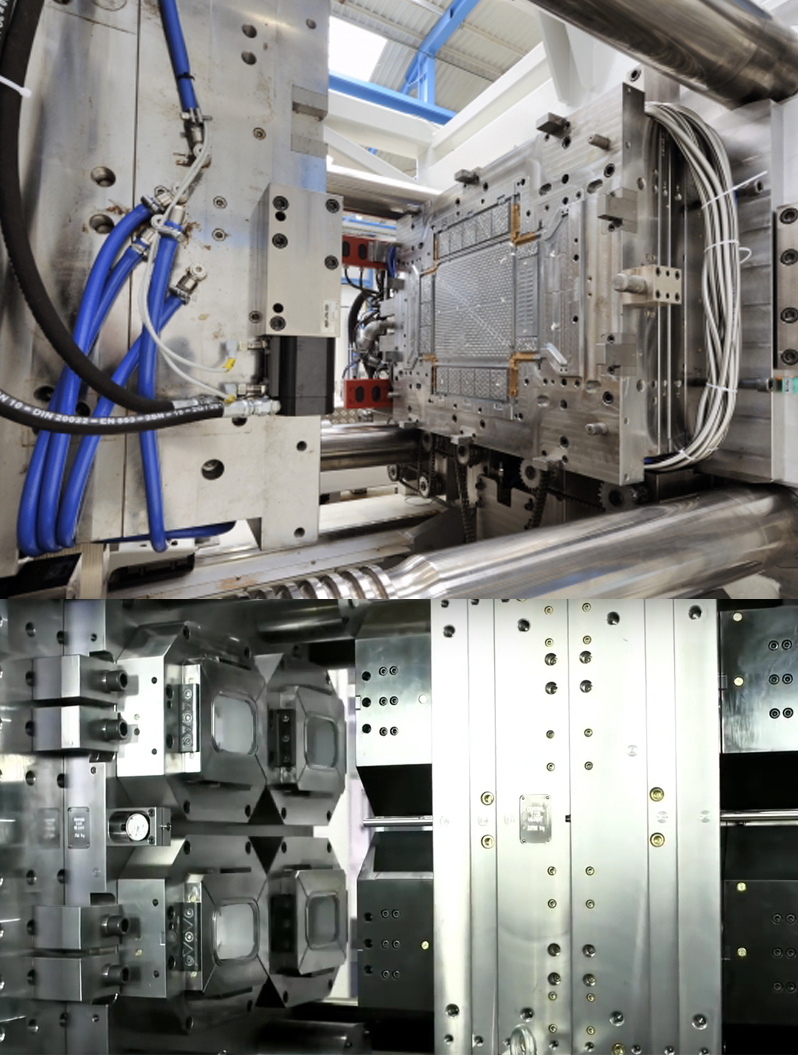

Mold fabrication and design happens when you have your own part design or sample to replicate. As every injection molding requires a mold to shape the molten plastic part, this is the very first step in entire process. We know how critical it can be so we always involve in the discussion of selecting mold material and the wall thickness to accommodate with the plastic resin features. At this stage, we have developed and establish links with other affiliates. We conduct mold flow analysis and transferring your 2D drawing to a 3D mold.

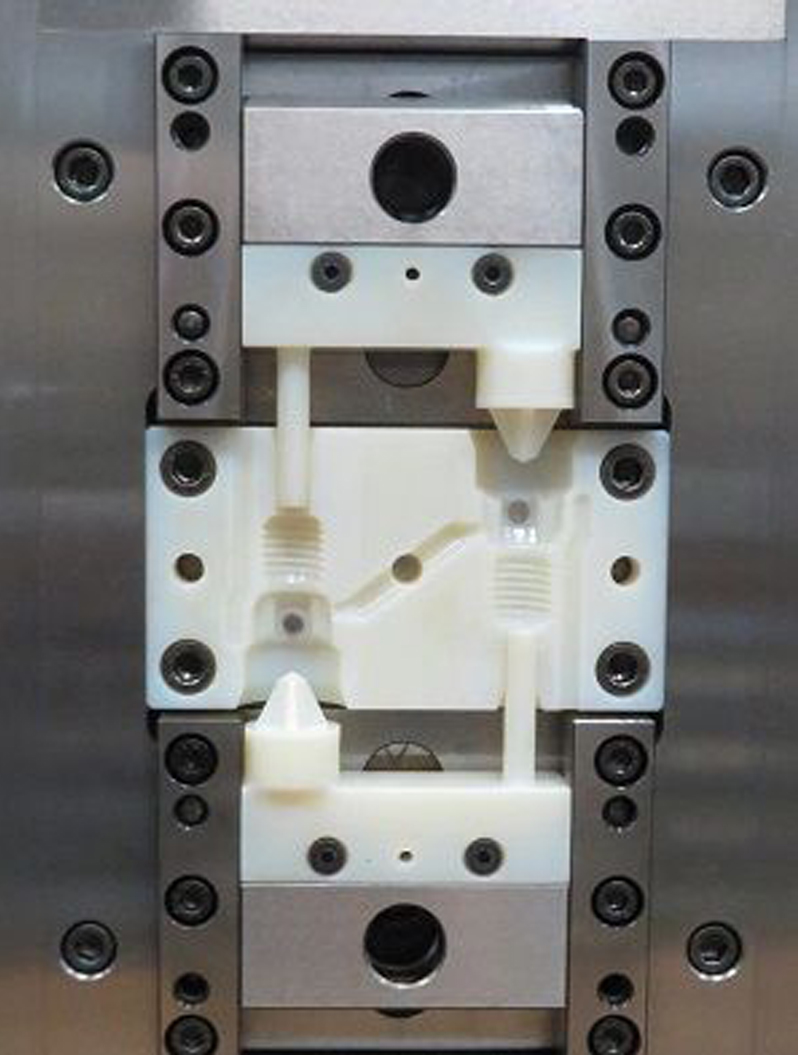

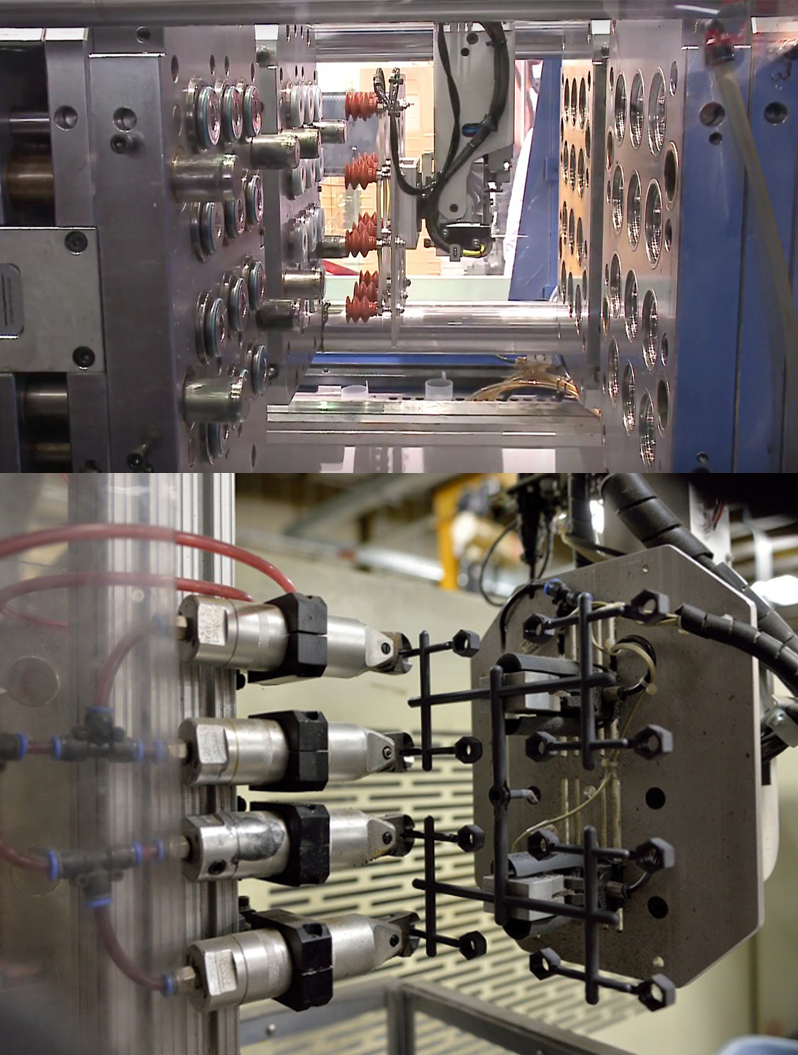

Mold testing is a need when you just develop your new mold. It is the period when your new mold is going for troubleshooting and trial, therefore a further modification is involved. We have a strong technical team to support on development and provide a solid advice after each result. To determine certain tolerances is needed in order to minimize tooling cost. Due to many years of operational experiences, we have been cooperated with other mold makers to accomplish their trial too.

Mass production comes in after any mold is developed and ready. We have a wide range of machines from 40 to 460 tonnages. In addition, we have around 22 injection machines. Besides that, our machines also well equipped with robot arms to fulfill automation process. Automation helps to reduce labor force and increase production output rate and increasing overall efficiency.

Spray painting is our value added services but we have developed a strong foundation and also part of our core business now. We have 2 water curtain spray booth with 4 manual sprays. We can handle 2k paint with hardener and lacquer spray. In addition, we have an isolated polishing department to provide a higher quality standard and satisfactions on our appearance part.

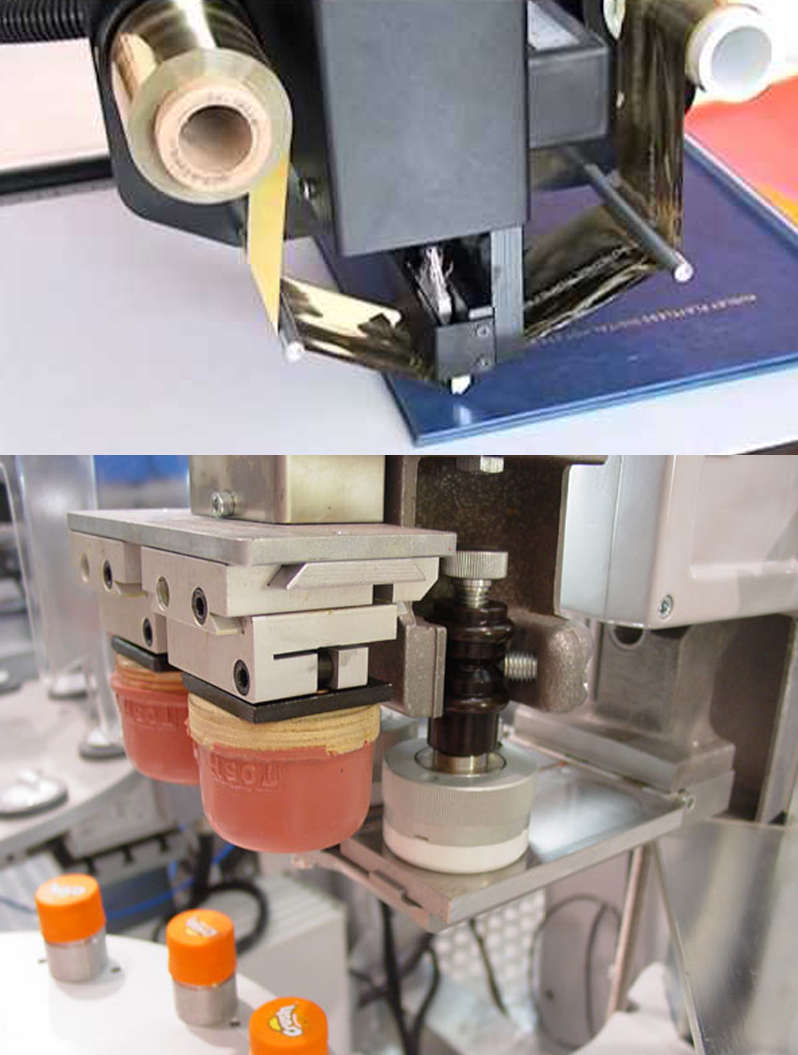

Our printing process can transfer your 2-D image onto a 3-D object. We offer a various value added services on printing such as silk screening, hot stamping, hot rolling, pad printing or tampo printing. We have 3 silk screens printing kits and 2 tampography machines. Therefore, our company has huge production capacity on printing services.

Assembly line is a manufacturing process in which parts are added as the semi-finished assembly moves from workstation to workstation where the parts are added in sequence until the final assembly is produced. We not only focus on producing raw parts to a coated with ink and paint plastic parts, we do offer assembly services. Understanding that customers need human power, we help our customers to assembly different raw parts to a finished good. In addition, we have 2 ultrasonic welding machines to assist in assembly too.

Address

No. 95,Jalan PJS 3/1,

Taman Medan, 46000 Petaling Jaya,

Selangor Darul Ehsan, Malaysia.

+(60)3 – 7781 8148

+(60)3 – 7781 8149

+(60)3 – 7781 8150

+(60)3 – 7781 8248

aaronqrsb@gmail.com

allan@qualityresult.com.my